Description

Financing Available

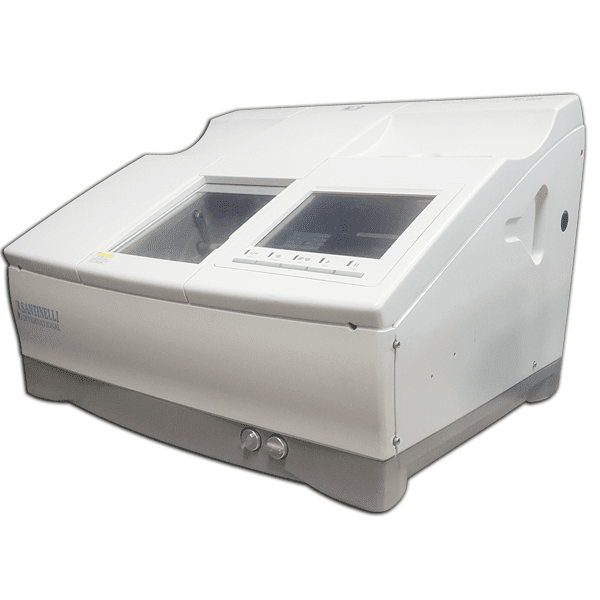

Santinelli Nidek ME-1000 Edger

The latest addition to the family of edging systems offers advanced functionality for creating an elaborate design lens of the highest quality.

The ME-1000 DESIGN+ has all the benefits of the ME-1000 and also integrates various functions for advanced lens design including Hole Creation, Shape Editor, Design Cut, Partial Grooving and Lens Facet. Each function assists you in your challenge toward more advanced and high-value lens

processing.

Features

- User Friendly LCD Touch Panel

- Binocular display

- High-Speed Grinding (15% Faster than Former Models)

- High-Speed RISC CPU

- Newly Developed 600W High Efficiency Motor

- Advanced Mechanics and High Accuracy

- LAN Ports for Convenient Data Transferring

- Grinding Chamber Motorized Cover

- Low Grinding Noise

Technical Specification:

Grinding System: Patternless Automatic, Guided, Flat, Polishing, Safety Beveling (with/without polishing), Grooving, Drilling (hole, slot, notch, etc.)

Lens Material*: Plastic (CR-39 and others), Polycarbonate, Acrylic, Trivex

*The type of lens material depends on the grinding wheel composition.

- Accessories: dressing sticks, pliable cups, pliable cup remover.

- Lens Size: 90 mm. or less

- Layout Range: 110 mm. or less

- Grinding Size*:

- Flat Edging 19mm

- Beveling 20mm

- *The minimum grinding size depends on the lens process specifications.

- Water Supply System: Pump Circulation or Mains Supply

- Power Supply: 240v

- Dimensions/Weight: 24.5″ (W) x 23.5″ (D) x 18″ (H) / 154 lbs.